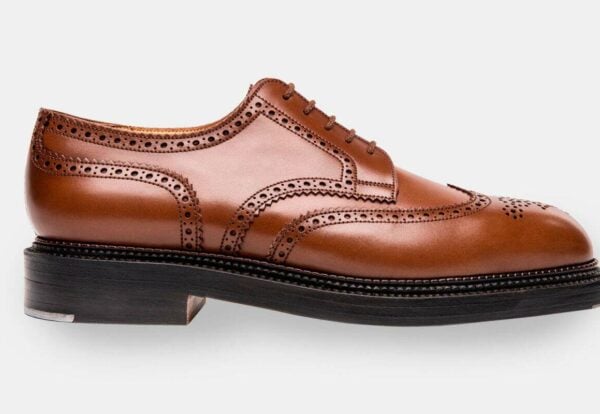

Yearn Shoemaker has been making some waves in the industry and here we are with a review to back it up. I first got ahold of this pair a few years back as it goes, and simply never got around to doing my written review after the successful reception of my unboxing video. But, as with the brand, this shoe deserves attention, not only for the make but also the price. There are few if any, better bang-for-your-buck shoes than what Yearn provides. So, let us take a look!

Construction:

The pair that Yearn shoemaker sent me was a completely handmade production shoe. That means it is hand lasted, hand welted and the sole stitch is done by hand. Now, that won’t necessarily mean that they don’t use sanding machines on the heel/sole finishing and use machines throughout the entire process. But the main stages are done by hand. While most that have read my blog for more than a year will probably know my stance on the abuse of the word ‘handmade’. For me, calling this shoe handmade would fall under the realm of acceptable. Trying to explain the difference between this and true bespoke is nearly a feat that has beat me. So, let’s call it handmade for the sake of simplicity.

It is very solid and well done make. It doesn’t try to make everything absolutely flawless like a Japanese bespoke shoe but everything is clean and tidy, the way it should be. You feel the sturdiness of the shoe and the fact that it is hand welted. If you have never worn one before there is a difference in feel with respect to a goodyear welted. It is hard to explain really, but often just feels more robust and supportive.

Fit:

The fit was the most peculiar thing, for me. After having discussed it more with the owner on it, we came to some understanding and I will preface this section with that. You see, what most people do not understand is that different cultures have different feet. You might think that this is crazy but it is true. And of course, everyone within a culture of people won’t be exactly the same but the stereotypes of their feet usually stay quite true.

For example, Dominicans have high insteps as do many French people. Now do not ask me why but I have observed this in my 20 years of fitting people, selling shoes and being married to a Dominican, and having seen their feet across a broad spectrum. That being, Tim Liu, the owner of Yearn explained to me that Chinese people (another client of mine confirmed the same) have lower ankle bones and often complain of the side panel of the top line of the shoe rubs them wrong on the ankle. So they naturally make a lower cut side panel and heel counter and accommodate their mostly Chinese customer base.

I noticed this when I tried the shoes on as a low-cut heel gives the sensation of coming out of the heel, at least for me it does, and is something that just felt off for me. I shared this in my unboxing video and I believe they have started to alter the shoes they offer for Asia and for outside of Asia. Lets see as I have a new pair soon to be unboxed.

The rest of the shoe was quite standard. The forefoot was generous without being over-voluminous. Most chisel lasts are generous so it seemed quite on par. The instep was low but I know that in a lazyman it kind of has to be to start as the only thing holding you down is some elastic on the sides. And that elastic always stretches. So, a snug instep is good in this case. I took my standard fit and it felt like the right size despite the heel slip from the low-cut heel. I could not have gone smaller and larger would have been too large. Therefore, i recommend sticking with your standard size.

Flaws:

I saw none to be honest. Again, the point here is to make a solid shoe, not a flawlessly perfect shoe. But there were no real flaws anywhere. It was a very simple, clean make with a very simple, clean finishing. You can see in the photos. If one really wanted to make a stink about nothing they could say that the fudging on the welt was not 100% consistent on the toe but to do so in a chisel last is nearly impossible without doing it by hand and even doing it by hand it is still one of the hardest steps in shoemaking to get flawless. But I know many people love to complain about nothing so here is your only thing to potentially gripe out. For me, it was top-notch for this caliber of making.

Overall:

To be honest, Yearn Shoemaker is one of the brands to be most concerned about in terms of their competition. It literally offers among the best value for money there is. To get a completely handmade shoe under $500 is insane. But I do not think it will last long. They can offset their pricing as they own other brands made for the Chinese market but I do believe they will have to continue to raise their prices at this quality level. When I first got these they were $399. Now they are $480. Don’t be surprised if in 2024 they get close to $600.

So you know what that means? Grab them while you can!

The owner is a great guy that speaks perfect English so don’t be afraid to reach out for any questions or concerns when wanting to place an order.

Start here: https://yearnshoemaker.com/

I own two pair of yearns with two more on order. It has been trial and error for me in terms of fit. I’ve been working with Jamie from Arterton (highly reccomend you buy your Yearns from him) and had to fo up a half size and to a wide fit to get the shoe fit correct. I take standard size in my J Fitzpatrick, TLB and Carlos Santos for comparison. I agree with Justin in that hand lasted / hand sewn shoes feel different compared to goodyear construction. You will not find a better pair at this price point than Yearn. And they offer MTO for only a $50 upcharge. As Justin says, buy them before Yearn raises the price to match the value and quality of what they are producing.

Thank you for sharing Michael!