In the dress shoe world, there are two main types of calfskin: Box Calf and Crust Leather. Most people understand what box calf is so here we shall focus mainly on crust leather as it is the one that I find causes more confusion. Simply put, crust leather is the rawhide tanned but not dyed, at the tannery. So it is finished naturally in order for someone else to apply the color after the fact.

Why Is It Called Crust Leather?

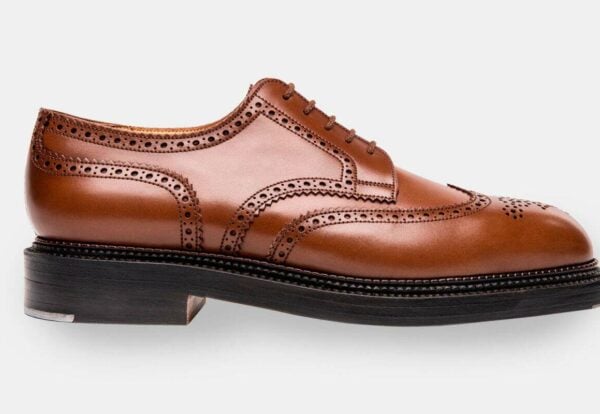

It is called crust leather because, well, crust is the term for a natural outer coating of a surface. One dictionary definition is “the hard outer shell or covering of an animal.” So, leather being an animal’s hide, the term crust is simply used to describe a more natural state left after tannage. And because of that, it is always in a natural, unfinished color. However, while it is tanned and dried and not dyed through, a crust can have a surface dye coating after the fact (not dyed through like a box calf), which is quite common for English shoe manufacturers to use. This top coating can also be done by the shoe factory itself and does not have to be done by the tannery. There is the option to buy plain, natural crust and/or top-coated crusted with a base layer, as you see in the image below.

Why Make Crust Leather?

At one point I am sure that tanneries were probably getting requests either for custom coloring or for blank canvases in order for the factories to have a go at putting their own treatments on the hides. With the rise of the Italian shoe factories and French shoe brands making colorful shoes of various shades, styles, and with patina looks, the crust leather option grew and grew. And now each tannery offers some sort of crust option as it is now extremely commonplace. With crust leather, any color is achievable on quality calfskin.

While I am sure that high-end tanneries could make pastel pink or lime green box calves, the reality is finding a classic shoe brand to buy that would be like finding a needle in a haystack. But allowing them to buy a natural and put those colors on if they want and when they want, is a far smarter business. Also, when making unique colors such as those, it is far more common to have them with a variation. A box-calf-style lime green shoe would not be the easiest thing to swallow. But if it had some depth to it with darker shading in certain parts of the shoe, it could easily make it more appealing.

So crust leather became very commonplace in the industry as the rise of unique and custom colors has gained popularity in the last few decades.

Is It Better or Worse Than Box Calf?

There is no way to answer this. They both have their positives and negatives. Crust calf tends to be softer (the drum dye stiffens the leather). It tends to shine easier too. But it is more susceptible to being affected by moisture, which means it can stain easier, and lose its finish easier too. But on the flip side, because its finish can be lost easier, it can also be manually manipulated easier which means you can alter its color with polishing/dyeing and thus give it depth and variation. So it often ages more beautifully due to that variation. It also breaks in faster.

Some will find the above as positive attributes but others may not. So the reality is that it is not better, it is not worse, it different than box calf. But it does allow for more variation in color, which for a brand owner like myself is a positive. I love crust leather.

The Downside of Crust Leather

The hardest thing to manage with regard to crust leather can be its volatility. It is easily affected by moisture and considering moisture comes in all forms i.e. rain, drinks, polish, creams etc, it often requires more upkeep so to speak. But at the same time, said upkeep also needs to be done properly. A novice in shoe care can easily ruin a pair of crust leather shoes with over-application of the shoe care products. Spilled alcohol drinks can destroy a crust leather finish, whereas box calf would take it like a champ. So, while it’s beautiful, shines well, is soft and often more comfortable, its downside is not for the faint of heart. It will certainly teach you to hone your shoe care skills.

Your definition of crust is a bit off. Crust leather is leather that only has dye applied on the surface, as opposed to drum dyed (like box calf). But most crust leathers are dyed by the tanneries, and then delivered as “burnishable” hides.

sorry, but that is not accurate. What you are indicating is a type of crust, but not the only crust. Crust is an undyed leather through the tanning process. It can then have a surface dye applied as a top coat, yes, and that I did not explain better, which I have now added. But crust leather is natural from the tannage and then dyed after the fact, unlike box calf which is drum dyed and finished all at the tannery. I buy tons and tons of natural crust leather for my own brand of shoes, so know a thing or two. And yes, many crust leathers are supplied with a base coat color. Particularly in the UK. But I am unsure if ‘most’ are. Many, especially now with the rise of factory patina, are supplied natural with no base coating/color.

Thanks for this, I had no idea there were difference in the function of the leathers!

My pleasure Robert!

love the colours.

Thanks for sharing!