The world of shoes is a vast one. There are many different terms to describe not only the shoe’s style name, but also the manner in which it was made as well as the small details that you find on the shoe’s surface and it’s core. And while some of this knowledge might be trivial to many of you, I know that there still are many people who do not know (or confuse) the differences in construction of shoes, as well as their style names, such wing-tip vs. brogues vs. cap toes etc. So, to appease the request of others, I will go through them in a brief yet concise manner, but also leave you with detailed descriptions provided by other blogs & articles, that have explained more thoroughly the differences in shoe construction. For today’s discussions, I will go through some of the different shoe constructions and what I think about them. Next week, I will go through each of the shoe’s style names and will leave it open for commentary on what you would like to learn about in week 3.

Pictures are taken from various sources, including Rider Boot Co. and La Botte Web

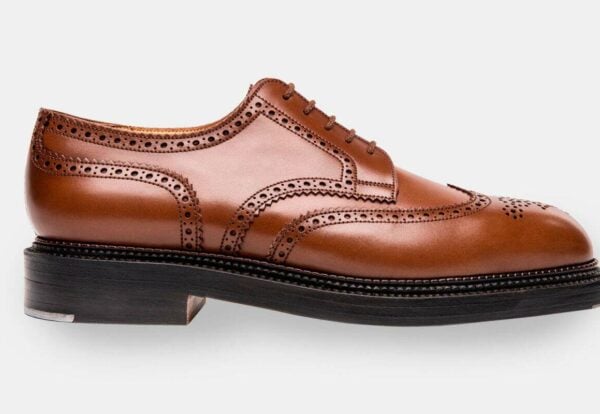

Shoe Above By: Roberto Ugolini

Shoe Constructions:

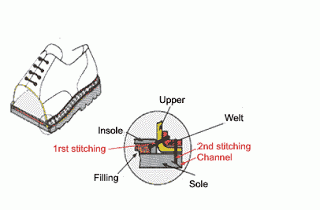

–Goodyear Welted:

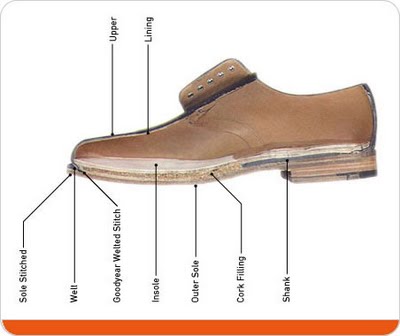

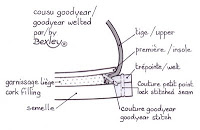

In my opinion, a Goodyear welted shoe, in terms of construction, is what separates the men from the boys. This is not to say that men who wear other constructions are boys, but in terms of a shoe’s integrity, Goodyear welted shoes will last you longer than most and therefore are the bread & butter of the high-end shoe market. It is generally regarded as the best construction in terms of comfort and durability as well as ease in terms of reparation. It also holds the same theory as bespoke welting, yet the obvious difference being that in bespoke it is done by hand and does not have a canvas rib supporting the feather. It is highly regarded for several different reasons: 1, for being relatively waterproof, because of the welt/sole connection, not allowing for water to get into the insole; 2, for it’s relative ease in replacing the sole, thus giving you a shoe that can truly last 20-30 years depending on how you treat the upper leather; and 3, for it’s cork filling, which is known to create a nice mold of your foot, after a good amount of wear, providing an almost custom-like foot-bed. While Goodyear welted shoes, are used very much by the English shoe market, the term and machinery used to create such shoes, were actually invented by Charles Goodyear Jr., the son of American inventor, Charles Goodyear, whom invented vulcanized rubber.

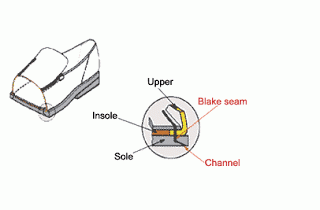

Blake & Blake Rapid:

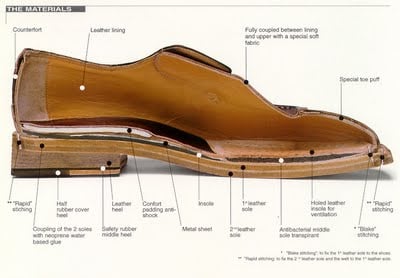

Blake and Blake Rapid are the constructions most used by the Italian shoe industry. The Blake construction is created by directly stitching the outer sole to the insole, providing maximum flexibility and a light weight to the shoe. The Blake Rapid construction is pretty much made in the same fashion, except that there is a mid-sole (as shown in the top picture) that is connected to the outer sole as well as the insole, providing a little bit more cushion to your foot. Some will say that a well made Blake Rapid, will be just as good as a Goodyear welted shoe, yet being the snob that I am, I prefer a Goodyear welted shoe. Not because I find it better, per se, but because that is what I have learned to make and appreciate. I do very much believe that a Goodyear welted shoe, will always out-trump a Blake constructed shoe on the other hand, as a Blake shoe is much easier to wear out and let water in. There are also far fewer cobblers who can repair a Blake constructed shoe, leaving you with a shorter life span of the shoe. Don’t get me wrong though, they are not necessarily to be frowned upon, they are just different, and it depends on what you are looking for.

Norwegian AKA Norvegese (in Italian)

Boots By: Santoni (true Norwegian stitch)

Bespoke Shoe By: Stefano Bemer (aesthetic Norwegian stitch)

Norwegian construction, despite it’s name, is a construction widely used, again, by the Italian shoe industry. While it was originally intended to create a shoe that was truly waterproofed, through and through, it is mostly used now to create an aesthetic appeal to those who appreciate it (i.e. picture of shoe by Stefano Bemer, above). That being, as you will notice in the two pictures, on a shoe that is intended for waterproof-like qualities, you will see that the welt is actually flush not only with the sole, but also with the upper, being completely on the outside, as opposed to halfway out and halfway in, as in Goodyear welt construction. But the bottom picture will show you, that there is no welt fully on the outside but rather just the stitching that represents the Norwegian look. This will give you the look of Norwegian construction, but won’t give you the complete waterproof quality. This will be a construction that you would want to consider for a shoe that you will use for outdoor activities, leaving you open to get wet. It is a durable, yet stiff construction, but can stand the test of time.

There are many other constructions out there, such as Bologna construction, but they are the far and few between and to me, are less important. But IF YOU READ HERE, you will get a much more in-depth description of each of the constructions above, including Bologna.

Goodyear Welted Shoes Below By: Alden

Great writeup. Although i miss a little on the st. crispin construction. What can you tell about that?

Great writeup. Although i miss a little on the st. crispin construction. What can you tell about that?

Personally, I’ve always loved the look of a sleek Italian loafer more than the robustness of a proper British Goodyear-welted brogue or penny.

I know that any sudden gust of rain would quickly destroy the delicate works of art but damn if they don’t make my broad ugly feet look slightly elegant.

I’m not sure sure how true it is, but I feel that a Blake constructed shoe allows my EEEE feet more flexibility to wiggle and breathe than a Goodyear-welted one. I won’t be surprised though, as Blake construction allows for far more bend (not that it’s a good thing) than a Goodyear-welt.

i think you will find that the major advantage of the goodyear or norwegian methods is that each stitch holding the welt also pulls the upper tightly around the last for a superior fit.

Dron – Thanks. I had never heard of the St. Crispin construction before. After researching for a little while, I dug up this:

http://www.comfortshoes24.co.uk/baer-craftsmanship/traditional-techniques/die-san-crispino-machart.html

It would seem that this construction is mainly for comfort walking shoes, which is why I would not be familiar with it, as I generally stick to dress shoe constructions.

Benjy – I understand your sentiment. A goodyear welted shoe is definitely going to be a little bit broader and when adding that to already wide feet, it certainly does not help for trying to appear slim.

Theo – I have never thought of that before nor heard it either, but I can definitely see what you mean and agree with it. Thanks for the input.

-Justin, “The Shoe Snob”

Thank you for the help, justin.

I own a pair dress/fashion boots with that construction so I thought there were more to it, but I guess in this case it was chosen for the aestethics only. They do look good though. IMHO

Thank you for the help, justin.

I own a pair dress/fashion boots with that construction so I thought there were more to it, but I guess in this case it was chosen for the aestethics only. They do look good though. IMHO

Dron – No worries my friend!!

-Justin, “The Shoe Snob”

Thank you very much for your intresting blog. I am from Russia and i find here so usefull infirmation.

I have some question about Goodyear Welted technology. Could you please explain how the upper leather conect with insole?

Natty – Sorry for this late reply, I was having troubles with my comments for a few days. The way that you connect the upper leather to the insole is through the welt. What you do is create a wall (or feather within the insole) that you then affix the welt to while at the same time poking a hole through the insole (wall), welt and upper leather to attach them all together. It’s hard to explain but if you look at the pictures carefully you should be able to understand it. If not, then go to Carreducker’s blog, on the right side of my page and search for a point in which they are showing this. Hope that this helps.

-Justin

With all due respect, I think you are mistaken about Goodyear construction being the choice of many (if any) bespoke makers.

Handwelted (a direct welt to upper to insole connection is the preferred method among almost every bespoke maker I know of or am familiar with. Carreducker–handwelted, Delos–handwelted, Lobbs, St James–handwelted, G&G bespoke–handwelted AFAIK.

Goodyear construction involves gluing a canvas rib (gemming) to a generally inexpensive insole…sometimes not even leather. A machine sews the welt, and upper to canvas ribbing but fundamentally, the binding principle is entirely dependent on the glue holding the gemming in place.

It makes no sense for a bespoke maker to hand inseam to a glued-on canvas rib when the same technique–inseaming directly to a high quality leather insole–will give vastly superior results.

DWFII – I did not know that you read the blog, but glad to see you on here. I think that I was slipping up with my words, since I have made shoes before entirely by hand, being naive to the fact that the term ‘goodyear’ strictly referred to machine made. I was under the impression, for some unknown reason, that goodyear referred to the use of a welt and the way that it was attached not thinking that doing it by hand, was not referred in the same way but actually just called hand welted. Therefore, you are right, of course, but I just misused the wording and do not think that bespoke makers used canvas ribs. What you stated is evidently obvious, especially when you explain it. It makes no sense to use a canvas rib only to then stitch by hand. But I am glad that you commented in order to point that out for this post and future reference, so I do not make the mistake again.

-Justin

Dear Anon – Hopefully you get this answer as I accidentally deleted your comment while trying to publish it (on my small phone…). Any to answer your question, best to start with neutral. However some threads are stain proof, in the sense that no matter what, they will not change color no matter what you use to polish them….best to test this on the inside heel as it’s the most inconspicuous part of the shoe…hope that this helps..

-Justin

some but few high end goodyear welted shoes do not use a canvas rib but a channel chiselled out of the insole as for hand welted

You are not a snob, just a prat.

Please stop blogging.

omg, you are so right. I think that due to your infinitely sage advice I will stop blogging and thus stop providing the useful and insightful information that many of my readers come to obtain on my site. Because why else would I not listen to someone called “fed up with your shit,” I would be foolish not to…….. seriously, get a life man!

yes, you are right…but they are very few…

I think the discussion on Norwegian welt is a bit light- it actually is as good, if not better than the Goodyear welt. I’ve got a pair of fabiano hiking boots bought in 1978 that are still going strong – would never trade for anything else. goodyear is great on my Aldens, more refined looking, and works great- but I think the Norwegian is superior in any outdoor and work boot situation

you are right, in any outdoor situation, it is far superior than just a GY welt..

does anyone have any references from journals about footwear construction???

That was a very clear explanation. It helped me understand more about why I would pay a lot of money for a pair of shoes. I’ve been buying SAS. I live in a small city and that is the best we have here, but I realize there are other brands out there.

glad that you enjoyed it Louis

Thx for your explanation of the Norwegian and Goodyear soles. I am seeking a pair of backpacking boots. This is helpful information. I have a requirement for an orthotic lift and am seeking manufacturers making a product that I might have adjusted for my need. Decades ago I had purchased a pair of Raichle hiking boots and these were very comfortable and were modified for me to wear. should anyone have info regarding a modern backpacking boot which allows the lift to be built up on the outside, I would be very grateful. I hope to be backpacking later this summer. Thx in advance.

Did you ever find someone? I’m in the same predicament.

hi there, I am doing some pereonal research on hiking boots and shoes and was just reading about the Peter Limmer boots and I think they do custom made hiking boots, you might want to check them out.

Easy to understand! I was just looking for a clear explanation. What about the Sacchetto Bologna construction? I am new at this topic and I get confused between the Blake rapid and the Sacchetto Bologna. Can you please mention some differences between this two styles of construction. Thank you!!

my son is a big man – 6’4″ and about 250 pounds. I am interested in getting the Pikolinos shoes for him, but am afraid the shoes aren’t sturdy enough for his size. They are a good leather and seem to have a good stitch – do you know anything about that shoe and if it would be good for a big man?

Hello, I have a few pairs of shoes that fit to tight that are size 12/and a half. Being a shoemaker reconstruct the shoes by putting on a size 14 sole and making them into a D width. The right shoe needs to have a High Toe Box the shoes are a Black&White Suede and another pair of Blue&Gray Suede with a High Toe Box. Reconstruct them into 14 D.

I have no clue what you are asking or saying, to be quite honest. Sorry. Is it a question or a statement?